When purchasing seamless tubes, many buyers are often attracted by low quotes, unaware that these seemingly "cost-saving" choices may lead to greater economic losses. Behind low-priced seamless tubes often lie hidden quality risks, which gradually emerge during use and ultimately result in losses several times the price difference.

Direct Losses from Quality Defects

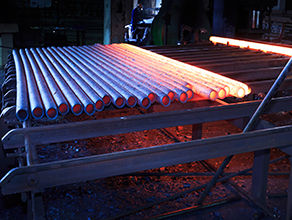

The most common issue with low-priced seamless tubes is substandard material composition. To reduce costs, some manufacturers use unqualified raw materials or reduce the content of alloy elements, resulting in tubes that fail to meet mechanical performance requirements. Such tubes are prone to early failure during use, requiring frequent replacements, which not only increases material costs but also leads to production line downtime losses.

Insufficient dimensional accuracy is another common problem. Low-priced seamless tubes often lack precise production control and inspection, leading to significant dimensional deviations that complicate subsequent processing and installation. Additional adjustments and corrections during installation often incur hidden costs far exceeding the savings from the initial purchase.

Long-Term Costs of Reduced Service Life

High-quality seamless tubes typically have a service life of several decades, while low-priced products may require replacement within a few years. In industrial pipeline systems, for example, replacing seamless tubes involves not only material costs but also expenses for dismantling, installation, and debugging, which often amount to several times the cost of the tubes themselves.

Moreover, low-priced seamless tubes often exhibit poor corrosion resistance, requiring more frequent maintenance and upkeep during use. These maintenance costs can accumulate significantly over time, particularly in corrosive environments such as chemical or marine applications.

Hidden Losses in Production Efficiency

Substandard seamless tubes are prone to various issues during use, such as leaks and fractures, leading to unplanned downtime for repairs. The losses from a single unplanned downtime may far exceed the total cost of all the seamless tubes purchased. This is especially critical for continuous production enterprises.

Additionally, issues such as reduced product qualification rates and increased energy consumption caused by poor tube quality indirectly raise production costs. These hidden costs are often overlooked during procurement but accumulate over time during use.

Potential Costs of Safety Risks

The most severe hidden cost arises from safety risks. Low-priced seamless tubes may contain undetected defects that could lead to failure under extreme conditions such as pressure or temperature, causing safety incidents. Such accidents not only result in direct economic losses but may also lead to immeasurable consequences such as personnel injuries and damage to corporate reputation.

Tenjan Steel Tube Co., Ltd. recommends that buyers comprehensively evaluate the total lifecycle cost of seamless tubes rather than focusing solely on the purchase price. With a strict quality control system, the company ensures every seamless tube meets standard requirements, helping customers achieve true cost optimization.

Choosing Tenjan means choosing peace of mind. For more product information, please call 0519-88789990 or visit our website at https://www.tenjan.com/. We will provide you with the most cost-effective seamless tube solutions.

Home Product Capabilities Case Studies Blogs About Get a Quote

Shapes & Profiles Pipe & Tube Manufacturing Process Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars Seamless Steel Tubes Special-Shaped Seamless Steel Tubes

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap