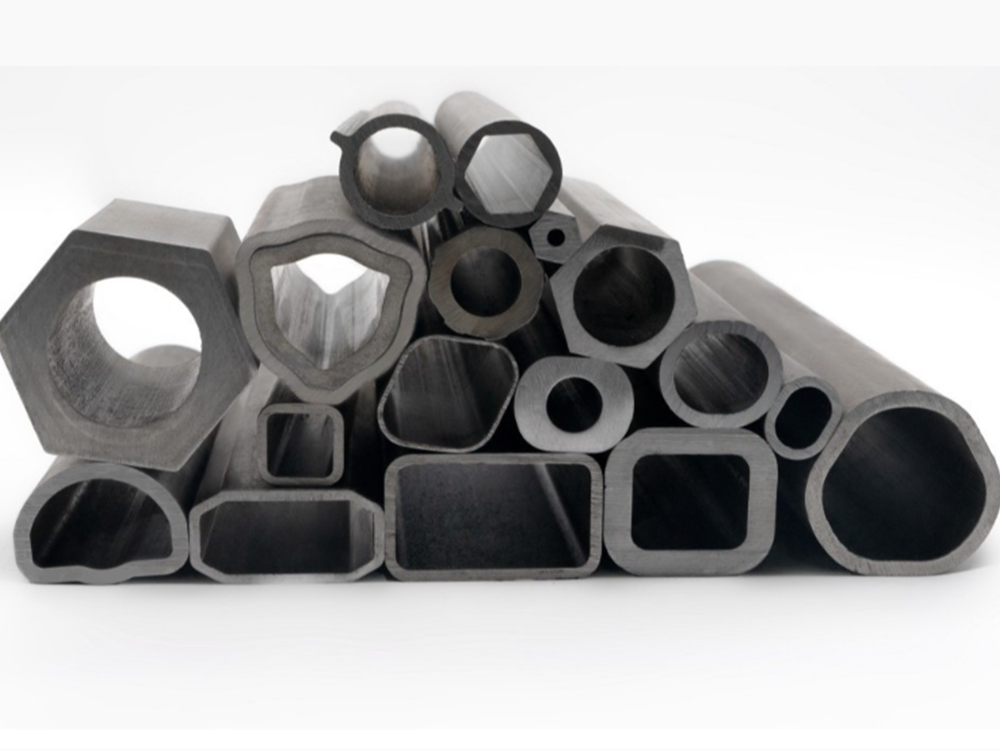

Tenjan Company offers high-quality seamless steel pipes and precision seamless tubing. These products are manufactured through advanced cold drawing technology and cold rolling processes. These hollow structural components with different cross-sections are specially designed to exhibit outstanding performance in harsh application environments, possess excellent compressive strength and structural reliability, and significantly reduce weight and material costs.

lnquiryDetail

Tenjan Precision Seamless Steel Tubes are cold-formed tubular products manufactured for applications requiring better dimensional consistency and surface quality than standard seamless tubes. These tubes are particularly suited for automotive components, hydraulic systems, and mechanical parts where reliable performance and ease of further processing are essential.

lnquiryDetail

Cold-Drawn Seamless Steel Pipes, also known as precision-drawn tubes or cold-finished seamless pipes, represent our high-precision product line manufactured through advanced cold-drawing technology. These precision cold-drawn tubes are produced by drawing seamless steel billets through precision dies at room temperature, resulting in superior dimensional accuracy, excellent surface finish, and enhanced mechanical properties that significantly outperform conventional hot-rolled pipes.

lnquiryDetail

Cold-Rolled Steel Tubes, also known as fine-rolled seamless tubes, are manufactured through an advanced process where steel shells are precisely rolled over mandrels using controlled roller systems. This sophisticated rolling technology applies calculated radial pressure while maintaining steady axial movement, producing tubes with exceptional dimensional consistency and reliable mechanical properties.

lnquiryDetail

Annealing represents a crucial delivery condition for precision steel tubes, commercially designated as GBK(+A) condition. Annealed Steel Tubes in GBK condition constitute a specialized category of precision steel pipes that have undergone complete annealing treatment after cold forming processes. These stress-relieved seamless tubes are manufactured according to international standards including DIN 2391, EN 10305-1, and GB/T 3639, featuring optimized mechanical properties achieved through controlled annealing processes in protective atmospheres.

lnquiryDetail

Quenched and Tempered Steel Pipes (Q&T ) represent advanced heat-treated steel tubes that undergo precise "quenching + high-temperature tempering" processes. These special heat-treated tubes are engineered to achieve optimal balance between strength and toughness through the formation of tempered sorbite microstructure, making them ideal for heavy-load and high-pressure applications in demanding working conditions.

lnquiryDetail

Normalized Steel Pipes (NBK/+N Condition) represent a standardized delivery state where steel tubes undergo normalizing heat treatment after cold forming processes. These normalized seamless tubes are heated to 30-50°C above Ac3 (for hypoeutectoid steel) or Accm (for hypereutectoid steel) temperatures, maintained at this level, then cooled in air to achieve refined microstructure and balanced mechanical properties.

lnquiryDetail

Cold Finished (hard) Steel Pipes (BK/+C) represent a delivery state where steel tubes undergo cold forming processes without subsequent heat treatment. These hard-condition seamless tubes maintain their as-cold-worked properties, featuring high strength and precise dimensional characteristics that make them suitable for applications requiring rigid components without complex secondary forming operations.

lnquiryDetail

Cold Finished(Soft) Steel Pipes (BKW/+LC n) represent a specialized delivery state where steel tubes undergo cold forming followed by low-temperature stress relief annealing. These soft-condition seamless tubes balance the high precision of cold working with the improved plasticity from stress relief treatment, positioning them between hard condition (BK) and fully annealed (GBK) tubes in terms of mechanical properties and processability.

lnquiryDetail

Cold Finished and Stress-Relieved Steel Pipes (BKS/+SR Condition) represent a precision delivery state where steel tubes undergo specialized stress relief annealing after cold forming processes.

lnquiryDetail

Tenjan delivers fully customizable cold-drawn welded tubes in both standard round and specialized profiles. Our engineered solutions adapt to your exact application requirements.

lnquiryDetail

Tenjan delivers fully customizable Cold-Rolled welded tubes in both standard round and specialized profiles. Our engineered solutions adapt to your exact application requirements.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap