In industrial equipment procurement, seamless steel pipes serve as critical materials whose quality directly impacts project safety. However, the market is plagued by fraudulent practices where welded pipes are misrepresented as seamless steel pipes, posing serious quality risks and economic losses to buyers. This article provides practical identification methods from a professional perspective to help you effectively mitigate risks during procurement.

Appearance Inspection: Identifying Welding Marks

Genuine seamless steel pipes are manufactured through a process of perforating and rolling round steel, resulting in a completely seamless structure. Even when welded pipes undergo refined processing, traces of welding often remain. First, inspect the pipe surface for straight-line marks, which may indicate treated weld seams. Using a magnifying glass for closer examination is recommended, as welded pipes frequently exhibit slight color variations or textural differences.

Another effective method involves examining the cross-section at both ends of the pipe. Seamless steel pipes display a uniform microstructure throughout, whereas welded pipes show distinct metallographic structures in the weld area. Additionally, inspect the inner wall of the pipe. Welded pipes often retain welding marks or burrs on the inner surface, while genuine seamless steel pipes feature a smooth and uniform interior.

Sound Test: A Simple Identification Method

A tapping test serves as a simple yet effective preliminary identification method. Gently tap the pipe with a metal rod. A seamless steel pipe will produce a clear, resonant sound with uniform echoes, while a welded pipe will emit a duller sound due to the presence of weld seams. The sound may also vary noticeably at the weld location.

Although this method cannot serve as a definitive judgment, it is useful for quick on-site screening. If any sound abnormalities are detected, further testing is necessary.

Professional Testing: Reliable Verification Methods

Ultrasonic testing is one of the most reliable methods to distinguish between seamless and welded pipes. Professional ultrasonic flaw detectors can accurately detect the presence of weld seams. Even when welded pipes undergo refined processing, ultrasonic testing can identify material discontinuities.

Metallographic analysis is the most scientific identification approach. By preparing and examining metallographic specimens under a microscope, the material's microstructure can be observed. Seamless steel pipes exhibit a homogeneous microstructure, while welded pipes display distinct weld zones, heat-affected zones, and base material regions.

Document Verification: Reviewing Quality Certifications

Reputable seamless steel pipe manufacturers provide comprehensive product quality documentation, including material certificates, production process records, and inspection reports. Scrutinize these documents carefully, paying special attention to whether the production process is explicitly stated as "seamless."

Additionally, request that suppliers provide qualification certificates from the manufacturer, such as special equipment manufacturing licenses and quality management system certifications. Changzhou Tenjan Steel Tube Co., Ltd. emphasizes that reputable manufacturers are transparent and willing to provide complete qualification documents.

Supplier Selection: The Fundamental Approach to Risk Mitigation

Selecting formal and professional suppliers is the most effective way to avoid purchasing counterfeit seamless steel pipes. As a professional seamless steel pipe manufacturer, Changzhou Tenjan Steel Tube Co., Ltd. recommends the following during procurement:

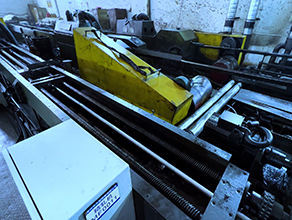

First, choose qualified and reputable suppliers, preferably through direct partnerships with manufacturers. Second, conduct on-site inspections of the supplier's production equipment and processes, as genuine seamless steel pipe production requires specific perforation and rolling machinery.

Furthermore, understand the supplier's after-sales service policies. Reputable manufacturers like Changzhou Tenjan Steel Tube Co., Ltd. offer comprehensive quality assurance and after-sales service systems, committing to "full refunds or replacements for quality issues."

Conclusion

Distinguishing welded pipes misrepresented as seamless steel pipes requires a combination of methods, ranging from visual inspections to professional testing, and from document verification to supplier evaluation. Maintaining vigilance during procurement and selecting formal channels are crucial to avoiding fraudulent practices.

As a professional seamless steel pipe manufacturer, Changzhou Tenjan Steel Tube Co., Ltd. adheres to integrity-based operations. All products are manufactured using authentic seamless processes and accompanied by complete quality documentation. The company maintains a robust quality traceability system, ensuring that every steel pipe can be traced back to its production process, providing customers with confidence in their purchases and applications.

For seamless steel pipe procurement or technical support, please contact Changzhou Tenjan Steel Tube Co., Ltd. at: +86-519-88789990 or visit the official website: https://www.tenjan.com/. Opt for reputable manufacturers and quality assurance to avoid procurement pitfalls and ensure project quality and safety.

Home Product Capabilities Case Studies Blogs About Get a Quote

Shapes & Profiles Pipe & Tube Manufacturing Process Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap