In the core units of the petroleum and chemical industry, petroleum cracking tubes serve as the "blood vessels" connecting reactors, heating furnaces, and heat exchange systems. Their quality directly determines the operational safety and production efficiency of the entire unit. As the core material for this critical role, seamless steel tubes have become the preferred choice for petroleum cracking tubes due to their irreplaceable performance advantages.

The Necessary Choice for Demanding Conditions

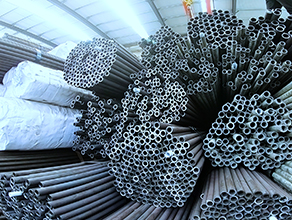

The petroleum cracking process involves high temperatures, high pressures, and corrosive media. Under such extreme operating conditions, any steel tube with a weld seam can become a potential risk point. Seamless steel tubes, manufactured through the integral forming technology of piercing and rolling round steel, possess a continuous and uniform overall structure without the weak point of a weld seam. This grants them exceptional creep resistance, enduring strength, and sealing performance, enabling them to comfortably withstand temperature fluctuations and pressure impacts reaching several hundred degrees Celsius within the cracking furnace.

The Key Role of Seamless Tubes in Cracking Units

In specific cracking units, such as delayed coking units or Fluid Catalytic Cracking (FCC) units, seamless tubes primarily undertake two core tasks:

1.Furnace Tube Applications: In heating furnaces, seamless tubes serve as furnace tubes, directly exposed to flame impingement to heat the internal crude oil or heavy oil to the cracking temperature. This requires the steel tubes to possess excellent high-temperature oxidation resistance and carburization resistance.

2.Transfer Lines: As connecting piping, they transport high-temperature oil-gas mixtures to subsequent systems. During this process, the tubes need to resist corrosion from sulfides, naphthenic acids, and other media, as well as high-temperature erosion and wear.

Tenjan Steel Tube Co., Ltd. deeply understands the stringent demands of the petroleum and chemical industry. The petroleum cracking seamless tubes they produce strictly select chromium-molybdenum alloy steel materials conforming to standards. Through precise heat treatment processes, they ensure their products possess stable high-temperature mechanical properties and corrosion resistance, meeting the needs of refining enterprises for long-cycle, safe, and stable operation.

Conclusion

In summary, in the modern petroleum and chemical industry, which prioritizes safety and efficiency, from the core of heating furnaces to complex process pipelines, seamless steel tubes, with their inherent structural integrity and reliable material properties, form the foundation of production safety. Manufacturers like Tenjan Steel Tube, who focus on technology and quality, are contributing indispensable strength to ensuring the smooth operation of the national energy industry chain by continuously providing high-performance seamless steel tubes for petroleum cracking.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap