Low-medium pressure boilers are crucial equipment in industrial production, and their safe operation directly impacts production efficiency and personnel safety. Selecting the appropriate seamless steel tubes is essential for ensuring the stable operation of the boiler system. This guide provides professional advice on purchasing seamless steel tubes for low-medium pressure boilers to assist you in making informed procurement decisions.

Material Selection and Standard Requirements

The choice of material for seamless steel tubes used in low-medium pressure boilers is the primary factor ensuring safe operation. Based on boiler operating parameters, high-quality steel grades such as 20G and 16MnG are typically selected. These materials offer excellent high-temperature strength and oxidation resistance, meeting the working condition requirements of low-medium pressure boilers. When purchasing, it is essential to confirm that the production of the seamless steel tubes complies with national standards, such as GB/T 3087-2008 "Seamless steel tubes for low and medium pressure boilers."

Changzhou Tenjan Steel Tube Co., Ltd. strictly adheres to national standards in the production of boiler seamless steel tubes, and all products come with complete material certification documents. The company recommends that customers select the appropriate material and specifications based on specific boiler operating pressure, temperature, and other parameters to ensure the product meets usage requirements.

Production Process and Quality Control

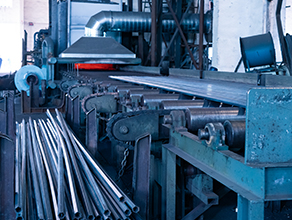

The manufacturing process of boiler seamless steel tubes directly affects their service life and safety performance. Seamless steel tubes produced by the hot-rolling process offer good comprehensive properties, while the cold-drawing process provides higher dimensional accuracy. Regardless of the process used, strict control of heat treatment parameters is necessary to ensure uniform material structure and stable performance.

Changzhou Tenjan Steel Tube Co., Ltd. has a comprehensive quality control system, implementing full-process quality monitoring from raw material procurement to finished product dispatch. The company is equipped with advanced heat treatment equipment, ensuring stable mechanical properties and metallurgical structure in the seamless tubes through precise control of process parameters.

Dimensional Accuracy and Surface Quality

The dimensional accuracy of boiler seamless steel tubes significantly impacts installation quality and operational effectiveness. Precise control of outer diameter and wall thickness ensures the sealing performance of the piping system, reducing leakage risks during operation. Simultaneously, good surface quality can effectively delay corrosion and extend service life.

When selecting tubes, close attention should be paid to geometric tolerances such as straightness and roundness. Changzhou Tenjan Steel Tube Co., Ltd. utilizes advanced straightening equipment and testing instruments to ensure product dimensional accuracy fully complies with standard requirements. The boiler tubes produced by the company have smooth surfaces, free from defects like cracks and folds, meeting the high standards required for boiler manufacturing.

Testing Requirements and Quality Certification

Seamless steel tubes for boilers must undergo rigorous testing procedures. In addition to routine chemical composition analysis and mechanical property testing, important inspection items such as hydrostatic tests and non-destructive testing are required. These tests can effectively identify material defects and ensure operational safety.

Changzhou Tenjan Steel Tube Co., Ltd. recommends that purchasers request complete product quality documentation from suppliers, including material certificates, heat treatment records, and test reports. All products dispatched from the company come with complete quality certification documents, and a quality traceability system is established, ensuring every seamless tube can be traced back to its production process.

Supplier Selection and Service Support

Choosing a reliable seamless steel tube supplier is key to ensuring procurement quality. Suppliers should possess relevant production qualifications and quality certifications, such as a Special Equipment Manufacturing License and ISO9001 Quality Management System certification. Furthermore, the supplier's technical capability and service support are important considerations.

Changzhou Tenjan Steel Tube Co., Ltd., as a professional manufacturer of seamless steel tubes for boilers, has a comprehensive technical service system. The company not only provides high-quality products but also offers professional technical consultation and after-sales service, ensuring customers receive full technical support throughout the usage process.

Installation and Usage Recommendations

Correct installation and usage are vital for ensuring boiler seamless steel tubes perform optimally. During installation, avoid forced assembly to prevent generating additional installation stress. During operation, strictly control water quality, conduct regular inspections and maintenance, and promptly identify and address issues.

The technical team at Changzhou Tenjan Steel Tube Co., Ltd. can provide professional installation guidance and usage recommendations based on customer needs. The company also conducts regular customer follow-ups to understand product performance and provide ongoing technical support.

Conclusion

Selecting suitable seamless steel tubes for boilers requires comprehensive consideration of factors such as material, process, and quality. It is recommended that purchasers select suppliers with professional qualifications and a complete quality assurance system to ensure product quality and usage safety.

Changzhou Tenjan Steel Tube Co., Ltd. is committed to providing customers with high-quality seamless steel tube products for boilers and comprehensive technical services. The company possesses a professional technical team and advanced production equipment, ensuring stable and reliable product quality. For more product information or purchasing advice, please call 0519-88789990 or visit the official website https://www.tenjan.com/. Choose professionalism, choose safety – let us provide a reliable seamless steel tube solution for your boiler system.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap