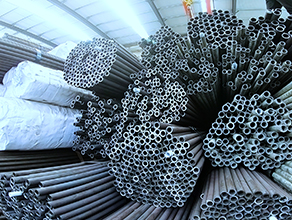

In the design of automotive hydraulic systems, small-diameter precision seamless steel tubes have become the preferred material for pipeline systems. This preference stems not only from their excellent performance but also from their ability to perfectly meet the stringent requirements of modern automotive hydraulic systems for safety, reliability, and space utilization. As the "blood vessels" of the hydraulic system, the performance of small-diameter precision seamless steel tubes directly determines the operational efficiency of the entire system.

Excellent Sealing Performance from Precision Dimensions

The primary advantage of small-diameter precision seamless steel tubes lies in their outstanding dimensional accuracy. Automotive hydraulic systems typically operate under high pressures of 20-40 MPa, where any minor dimensional deviation can lead to leakage risks. The outer diameter tolerance of precision seamless steel tubes can be controlled within ±0.05mm, with wall thickness uniformity within ±5%. This high precision ensures perfect sealing at pipeline connections.

Compared to traditional welded tubes, seamless steel tubes have no weld seam—a potential weak point—fundamentally eliminating leakage hazards caused by weld quality issues. The precision seamless steel tubes produced by Changzhou Tenjan Steel Tube Co., Ltd. utilize advanced cold drawing processes coupled with precision straightening technology, controlling the straightness of the steel tubes within 0.5mm/m, providing reliable sealing assurance for hydraulic systems.

Exceptional Mechanical Properties Ensure System Safety

Automotive hydraulic systems have extremely high requirements for the strength of pipeline materials. Through precise alloy design and heat treatment processes, small-diameter precision seamless steel tubes can achieve tensile strengths exceeding 800 MPa and yield strengths exceeding 600 MPa, fully meeting the material strength requirements of high-pressure systems. More importantly, seamless steel tubes are isotropic, maintaining uniform mechanical properties in all directions.

In terms of fatigue performance, seamless steel tubes perform particularly well. During vehicle operation, hydraulic system pipelines need to withstand continuous pressure fluctuations and vibration loads. Changzhou Tenjan Steel Tube Co., Ltd. optimizes heat treatment processes to achieve a product fatigue life of over 1 million cycles, ensuring reliable operation of the hydraulic system throughout the vehicle's entire lifecycle.

Superior Surface Quality Enhances System Efficiency

The internal surface quality of precision seamless steel tubes directly affects the transmission efficiency of the hydraulic system. Changzhou Tenjan Steel Tube Co., Ltd. employs special cold rolling and finishing processes to achieve an internal surface roughness of Ra ≤ 0.4μm. This ultra-smooth surface significantly reduces fluid flow resistance, improves system transmission efficiency, and simultaneously reduces particle adhesion, helping to maintain the cleanliness of the hydraulic fluid.

External surface quality is equally important. The uniform and smooth external surface of precision seamless steel tubes facilitates installation and fixation, while also providing an excellent base for surface treatment. The company can provide surface treatments such as phosphating and pickling based on customer requirements, further enhancing the product's corrosion resistance and service life.

Ideal Choice for Space Optimization

In modern automotive design, space utilization is increasingly emphasized. Through optimized diameter design and wall thickness control, small-diameter seamless steel tubes achieve miniaturization and weight reduction goals while ensuring pressure-bearing capacity. Compared to traditional pipelines, hydraulic systems using precision seamless steel tubes can save 20%-30% of installation space.

Leveraging extensive experience, Changzhou Tenjan Steel Tube Co., Ltd. can provide professional space optimization solutions. The technical support team can recommend the most suitable tube diameters and layout schemes based on the characteristics of the vehicle's overall layout, helping customers achieve optimal space utilization.

Reliable Assurance of Quality Stability

Automotive manufacturing places extremely high demands on the consistency of component quality. Changzhou Tenjan Steel Tube Co., Ltd. has established a comprehensive quality assurance system, certified to IATF 16949, ensuring stable performance for every batch of products. Full-process quality monitoring is implemented from raw material intake to finished product shipment.

The company is equipped with advanced testing equipment to conduct rigorous inspections on seamless steel tubes. This comprehensive quality control ensures that the products meet the stringent requirements of automotive manufacturers for quality consistency.

Comprehensive Reflection of Economic Benefits

Although the unit price of small-diameter precision seamless steel tubes is relatively high, their total lifecycle cost is more advantageous. As additional quenching and tempering treatments are not required, purchasers can process and use them directly, saving on heat treatment equipment and energy consumption. The longer service life and lower failure rates also significantly reduce maintenance costs.

Through process optimization and refined management, Changzhou Tenjan Steel Tube Co., Ltd. effectively controls production costs while ensuring product quality, providing customers with product solutions that offer the best cost-performance ratio.

Conclusion

Small-diameter precision seamless steel tubes, with their exceptional sealing performance, mechanical properties, surface quality, and space utilization, have become the ideal choice for automotive hydraulic system pipelines. Changzhou Tenjan Steel Tube Co., Ltd. will continue to dedicate itself to technological innovation and quality improvement, providing the automotive manufacturing industry with higher quality precision seamless steel tube products and comprehensive technical services.

For more technical information on precision seamless steel tubes for automotive hydraulic systems or to request product samples, please feel free to contact Changzhou Tenjan Steel Tube Co., Ltd. We will provide the most reliable material solutions for your automotive manufacturing projects with our professional expertise and extensive experience.

Contact Tel: 0519-88789990

Website: https://www.tenjan.com/

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap