In automotive suspension systems, the shock absorber tube, as a key component, faces persistent issues with fatigue cracking that concern numerous automobile manufacturers and vehicle owners. This seemingly simple seamless steel tube component actually endures complex and variable operational loads. Its failure often stems from the combined effect of multiple factors. In-depth analysis of the causes behind the fatigue cracking of shock absorber tubes is of great significance for enhancing vehicle safety performance and ride comfort.

Continuous Action Under Complex Stress States

During operation, shock absorber tubes withstand the combined action of multiple stresses. In addition to vertical impact loads from the road surface, they also bear bending stress, torsional stress, and thermal stress induced by temperature changes. This multi-axial stress state makes the surface of the seamless steel tube prone to developing micro-cracks, which gradually propagate under cyclic loading. Particularly during sharp turns or emergency braking, the shock absorber tube must endure additional lateral loads, further exacerbating stress concentration phenomena.

Potential Impact of Material Defects

The purity and uniformity of the seamless steel tube material directly affect the fatigue life of the shock absorber tube. Defects such as non-metallic inclusions, microscopic pores, and compositional segregation can all become initiation points for fatigue cracks. Research indicates that when the size of sulfide inclusions in the seamless steel tube exceeds 20 micrometers, the material's fatigue strength decreases significantly. Furthermore, surface imperfections like machining marks and micro-cracks can also rapidly develop into macroscopic cracks under alternating stress.

Critical Role of Heat Treatment Processes

Improper heat treatment processes are a significant reason for the early-stage fatigue cracking of shock absorber tubes. Residual stresses generated during the quenching process, if not adequately relieved through tempering, will superimpose with operational stresses during use, accelerating the accumulation of fatigue damage. Simultaneously, improper control of heat treatment temperatures can lead to coarse grains or microstructural inhomogeneity, reducing the material's fatigue limit. Surface decarburization of the seamless steel tube is also a common issue during heat treatment, significantly reducing the material's surface strength and wear resistance.

Accelerating Effect of Corrosive Environments

In corrosive environments such as those with humidity and salt, the fatigue life of shock absorber tubes is substantially shortened. The formation of corrosion pits not only reduces the effective load-bearing cross-section of the seamless steel tube but also creates severe stress concentration at the pit bottom. This damage mechanism of corrosion fatigue is more dangerous than pure mechanical fatigue because the interaction between corrosion and fatigue significantly accelerates crack initiation and propagation. This problem is particularly prominent in areas where de-icing salts are used in winter.

Detailing Issues in Design and Manufacturing

The structural design details of the shock absorber tube significantly impact its fatigue performance. Stress concentration areas such as sudden changes in cross-section, thread roots, and welded areas are prone locations for fatigue cracks. Issues during manufacturing like dimensional deviations, assembly stresses, and surface damage also reduce the fatigue strength of the seamless steel tube. Research shows that reducing the surface roughness from Ra 0.8μm to Ra 0.2μm can increase the fatigue life of shock absorber tubes by approximately 30%.

Influence of Usage Conditions

The vehicle's usage conditions directly affect the service life of the shock absorber tubes. Vehicles frequently driven under harsh road conditions subject their shock absorber tubes to greater impact loads, leading to faster accumulation of fatigue damage. Overloading significantly increases the working stress on the seamless steel tube, accelerating fatigue damage. Additionally, incorrect driving habits, such as speeding over speed bumps or taking sharp turns rapidly, impose extra impact loads on the shock absorber tubes.

Prevention and Improvement Measures

To address the fatigue cracking problem of shock absorber tubes, manufacturing enterprises should adopt systematic prevention and improvement measures. In terms of material selection, high-purity, uniformly structured high-quality seamless steel tubes should be used. In production processes, heat treatment parameters need optimization, with strict control over quenching cooling rates and ensuring adequate tempering. At the design level, abrupt sectional changes should be avoided, and rounded transitions should be adopted to reduce stress concentration.

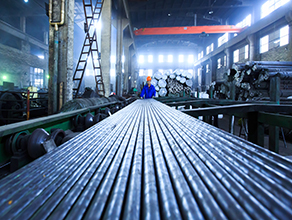

Changzhou Tenjan Steel Tube Co., Ltd., as a professional supplier of seamless steel tubes for automotive applications, has achieved significant results in the research and development of materials for shock absorber tubes. By optimizing alloy design, the company has developed special seamless steel tube materials with higher fatigue strength. Utilizing advanced smelting technology, the inclusion content in the material is controlled at very low levels. Simultaneously, by improving heat treatment processes, the products achieve a uniform and fine microstructure, significantly enhancing the material's fatigue performance.

The company has also established a comprehensive inspection system, conducting strict ultrasonic flaw detection, mechanical property testing, and fatigue tests on each batch of seamless steel tubes to ensure stable and reliable product quality. Leveraging professional technical expertise and stringent quality control, Changzhou Tenjan Steel Tube Co., Ltd. has become the preferred supplier for many automobile manufacturers. For more product information, please visit the official website at https://www.tenjan.com/ or call 0519-88789990 for inquiries.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap