Seamless Tubes represent a premium-grade, high-sulfur phosphorus lead-free free-cutting steel tubing engineered specifically for automated, high-speed precision machining applications. Unlike conventional structural steels, these American ASTM standard 1215 seamless tubes feature an ultra-low carbon content (≤0.09%), optimized manganese (0.75%-1.05%), and elevated sulfur (0.26%-0.35%), creating abundant MnS inclusions that act as internal solid lubricants during cutting operations, delivering superior machining efficiency and excellent eco-friendly compatibility.

Material Specifications & Technical Breakthrough

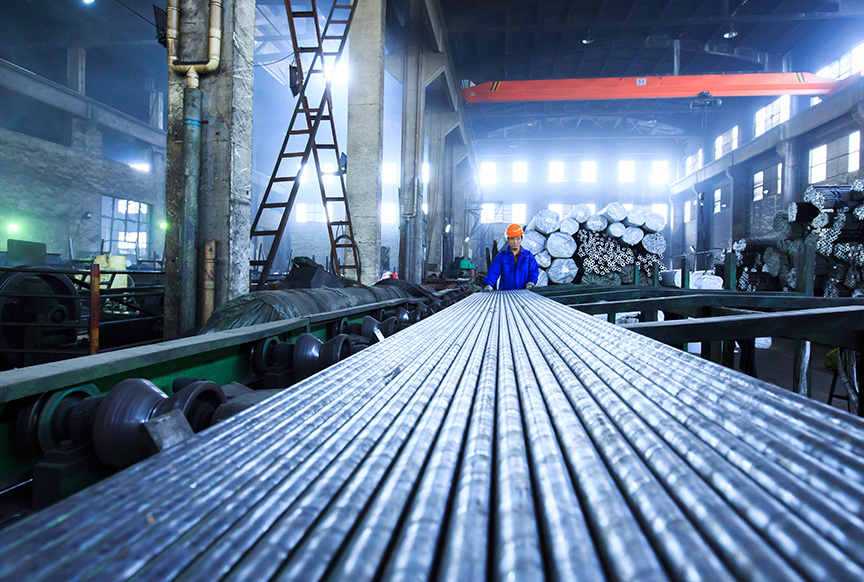

As a specialized lead-free free-cutting steel grade within the ASTM A29 standard system, 1215 seamless steel pipes represent Tenjan's groundbreaking achievement in conquering the production challenges of high-sulfur steel. Our proprietary low-temperature slow piercing and segmented temperature-controlled rolling technology enable full-process autonomous production, with dimensional ranges covering OD 6-325mm, wall thickness 1-30mm, and lengths up to 12 meters, effectively filling a critical domestic production gap.

Material Composition & International Equivalents

The precision-engineered chemistry guarantees exceptional machining performance:

• Carbon: ≤0.09% (ensuring superior plasticity and cold formability)

• Manganese: 0.75%-1.05% (forming crucial MnS inclusions)

• Sulfur: 0.26%-0.35% (the core free-cutting element)

• Phosphorus: 0.04%-0.09% (auxiliary chip-breaking element)

• Lead-Free: Fully compliant with EU RoHS, a true green machining steel

International equivalent grades include:

• China: Y15 (GB/T 8731)

• Europe: 11SMn30 (EN 10087)

• Japan: SUM23 (JIS G4804)

• USA (Leaded): 12L14 (ASTM A29)

Machining Performance & Technical Advantages

Exceptional Machining Characteristics:

• Extended Tool Life: MnS inclusions reduce tool wear by over 60%, tripling tool service life and slashing tooling costs.

• High-Speed Machining: Cutting speeds of 100-150 m/min, 1.5-2 times faster than ordinary carbon steel, drastically reducing cycle times.

• Perfect Chip Control: Produces short, brittle "C-shaped" or granular chips that prevent tool wrapping and enhance operational safety.

• Superior Surface Finish: Achieves surface roughness of Ra1.6-Ra3.2 directly from machining, eliminating secondary polishing.

Mechanical Properties & Environmental Benefits:

• Tensile Strength: 390-540 MPa (Hot-rolled)

• Yield Strength: ≥260 MPa

• Elongation: ≥22% (Hot-rolled)

• Hardness: 160-190 HB (Cold-drawn)

Eco-Friendly Composition: A direct lead-free alternative to 12L14 steel, perfectly suited for export-oriented manufacturing.

Applications & Industrial Solutions

1215 free-cutting steel tubes excel across automated, high-precision manufacturing sectors:

Precision Machinery & Automation

• Hydraulic system fittings and bearing bushings

• Coupling components and guide shafts

• Machining benefits: High inner bore precision (H7 grade), ensuring reliable sealing.

Automotive Manufacturing

• Brake system tubes and steering linkage parts

• Instrument panel support structures

• Production advantages: Excellent batch consistency, meeting strict automotive environmental standards.

Electronics & Medical Devices

• Heat sink conduits and precision instrument frames

• Surgical instrument accessories and medical equipment tubing

• Key features: Lead-free safety, easy-to-clean surfaces, and corrosion resistance.

Standard Component Manufacturing

• High-precision pipe fittings and thin-walled nuts

• Stud bushing and connector components

• Manufacturing edge: Single-pass machining capability, producing clear, precise threads.

Quality Assurance & Customization

All 1215 seamless tubing products undergo rigorous quality control, backed by ISO 9001 certification and independent performance verification. Tenjan's manufacturing flexibility provides customized dimensional solutions and tailored surface quality to meet your specific application requirements seamlessly.

Tenjan Advantage & Industry Leadership

As the exclusive domestic manufacturer mastering the production of 1215 free-cutting seamless tubes, Tenjan has overcome the inherent cracking challenges of high-sulfur steel. Our specialized capability allows us to produce a wide range of domestic and international free-cutting steel grades, all customizable to your unique machining needs. With end-to-end production control and expert technical support, we guarantee consistent material quality and reliable performance for your most demanding automated machining applications. Our responsive service and flexible order quantities ensure smooth project integration, upholding our commitment to delivering high-performance, eco-friendly cutting solutions that boost your manufacturing efficiency while supporting global sustainability initiatives.

Custom Sizes OD10-108mm - ASTM/EN/DIN/JIS/GOST Certified - Small-Batch Friendly

| Parameter | Key Features |

| Outer Diameter | 10-108mm (0.39"-4.25") • Fully customizable |

| Wall Thickness | 1-20mm (0.039"-0.79") • ±0.1mm precision tolerance |

| Material | Carbon Steel • Alloy Steel • Special grades available |

| Process | Cold Drawn & Cold Rolled for superior finish |

| Industry | Typical Grades We Supply |

| GB | DT4,Y15,10#,20#,20G,Q235,25Mn,35#,45#,55# |

| ASTM | 1215,1008,1010,1020,A105,A106 Gr.B,A36,1026,1035,1045,1055,SA179,SA192 |

| EN | DC01,11SMn30,P235TR1,P195GH,P265TR2,E235 |

| DIN | DC01,11SMn30,CK10,C10,ST35.8,C20,CK20, ST45.8,St37,S235JR,C26D,CK35,CK45,CK55 |

| JIS | SUM22,S10C,STKM11A,STPT370,STB35,S20C,STKM12, STKM13,STPT410,STB42,SS400,S35C,S45C,S55C |

| GOST | 08КП,10,20,Ст3сп,25,35,45,55 |

| Other Speical Grades can be customized | |

| Standard | Key Applications Parts | Relevant Standards | Our Advantages |

| Automotive and Motorcycle Component | Shock Absorbers,Steering Systems,Thrust Rods | EN 10305-1,JIS G3445, DIN 2391,ASTM A519 | High fatigue strength,High yield strength,lightweight,precision dimensions (±0.1mm) |

| Engineering and Mining Support | Anchor Bolts,Support Pipes,Hydraulic Props | ASTM A519,DIN 2391, JIS G3441,EN 10297-1, ISO 10799 | High Strength &Yield Strength&High Elongation Customization Service - Special steel grades,dimensions and surface treatments available according to project requirements |

| Construction Machinery | Drive shaft sleeves ,Gearbox Guide Tubes,Crane Boom Guide Tubes,Excavator Arm Tubes,Loader Frame Tubes, Arctic Low-Temperature Tubes | ASTM A519,DIN 2391, JIS G3445,EN 10210-1, GOST 8733,ASTM A106, ISO 9329 | ID/OD tolerances of ±0.05mm.Wall thickness uniformity straightness ≤0.5mm/m |

| Fluid Transport Systems | Oil/Gas pipelines,chemical systems,Power/Energy | ASTM A106 Gr.B, EN 10216-2,GOST 8734 | Eddy Current + Ultrasonic Testing,Hydrostatic Testing |

| High-Pressure Boilers | Superheaters,Steam lines,Reheaters,Economizers) | ASTM A192,DIN 17175, EN 10216, JIS G3461/G3462 | Enhanced material density through cold-drawing/rolling ensures long-term stability Full Compliance with Int'l Standards,Superior Creep & Fatigue Resistance |

| Geological Drilling | Drill Pipe,Tubing | ASTM A519,API 5DP, EN 10208-2 | High Strength & Wear Resistance precision Dimensions Impact & Fatigue Resistance |

| Agricultural Machinery | Hydraulic cylinders,drive shafts,Lift arms, steering housings,Boom frames | ASTM A519,EN 10210-1, DIN 2391,GOST 8733, JIS G3445 | Material Advantages:High Strength & Lightweight,Precision Cold-Drawing Technology,Dimensional accuracy ±0.05mm |

| Petroleum Cracking Units | Reformer Tubes,Heat Exchanger Tubes,Reactor Feed Pipes,Transfer Lines,Quench Oil Pipes | ASTM A335,ASTM A213, EN 10216-2 | Optimized Material Purity,Precision Dimensional Control,Customized Solutions |

Tailored Features · Designed Exclusively for Your Needs

Breakthrough in Pure Iron 1215 Steel Tube Mass Production – 30% Cost Saved vs. Solid Bar Machining Industry-First Innovation:

We’ve achieved mass production of precision soft iron carbon tubes and 1215 free-cutting steel tubes, eliminating costly machining steps for OEMs.

Key Benefits:

✔ 30% Lower Total Cost– Replace solid round bars (no boring needed)

✔ Faster Production – Reduced machining & assembly time

✔ Less Waste – Precision hollow tubes optimize material use

Applications: Automotive, Hydraulics, Fasteners, and Machined Components.

Cold Drawing + Cold Rolling Dual-Process Technology – Affordable Small-Diameter Seamless Steel TubesInnovative Production for Precision Tubes:

Our self-developed piercing mill combines cold drawing & cold rolling, optimizing efficiency for small-diameter seamless steel tubes (OD<50mm).

Key Advantages:

✔ Lower Cost – Dual-process reduces material waste & energy use

✔ Tighter Tolerances– Improved surface finish & dimensional accuracy

✔ Faster Lead Time– Streamlined production vs. traditional methods

Applications: Automotive, Hydraulics,Oil & Gas/Petrochemical,High-Pressure Boilers,and Fluid Transport Systems.

100+ Carbon Steel Grades – Customize for 20% Cost Savings (Machining,Construction More) Premium Steel Supply Chain:

Partnering with Baosteel, Xingcheng Shagang, we offer 100+ fully customizable carbon steel grades with guaranteed quality and stable supply.

Customization Advantages:

✔ Chemical Composition– Adjust C, Mn, Si, etc. for specific applications

✔ Mechanical Properties– Yield/Tensile strength optimization

✔ Rigorous QC– Full inspection (UT, hardness testing, dimensional checks)

✔ 20% Procurement Savings– Bulk pricing process efficiency

Key Industries Served: Machining Automotive,Construction Infrastructure, Oil Gas, Heavy Equipment

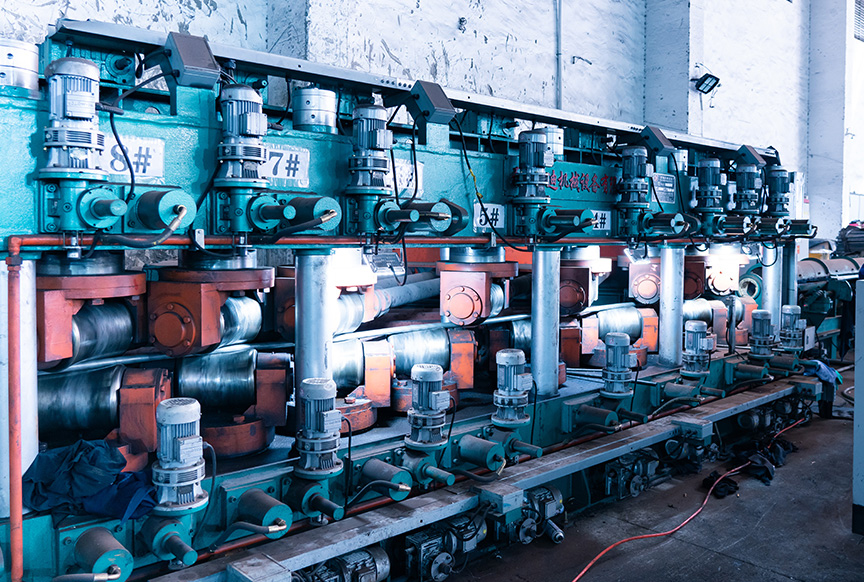

High-Precision Tube Straightening Technology - ≤0.5mm/m Tolerance for 30% Faster MachiningIndustry-Leading Straightening Solutions:

Our proprietary system delivers carbon steel tubes with ≤0.5mm/m straightness-4X more precise than industry standards, specifically engineered for high-speed machining applications.

Key Advantages:

✔ 30% Production Boost- Perfect straightness reduces lathe processing time

✔ Tool Life Extension- Minimizes cutting tool stress and wear

✔ Cost Efficiency- Lower maintenance and higher throughput

Technical Superiority:

In-House Developed Equipment- Customized for machining-grade precision

20+ Years Expertise- Master technicians ensure optimal results

Automated Quality Control- Consistent straightness verification

Ideal for:Hydraulic Cylinder Tubes, Automotive Shafts, Industrial Machinery, Oil Gas Equipment

Ultrasonic + Eddy Current Dual-Testing - 0.20mm Flaw Detection for Critical Steel Tubes Industry-Leading NDT Precision:

Our dual-technology inspection systemdelivers 0.20mm flaw detection accuracy- the gold standard for mission-critical tubing applications.

Dual-Testing Advantages:

✔ Ultrasonic Testing (UT)- Detects 0.20mm micro-cracks & inclusions

✔ Eddy Current (ET)- Pinpoints surface/subsurface defects

✔ Multi-Probe Array- 360° coverage (ID/OD/wall thickness)

Two-Layer Quality Assurance

Flaw Detection: Cracks/pores/inclusions ≤0.20mm

Dimensional Control: ±0.05mm tolerance verification

Critical Applications: Automotive Airbag Tubes,Fluid Transport Systems, Petrochemical High-Pressure Piping

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap