Heat treatment is a crucial process in the production of seamless tubes. Different heat treatment processes impart different performance characteristics to seamless tubes. Understanding the distinctions and applications of the three fundamental heat treatment processes – annealing, normalizing, and quenching & tempering – helps in better selecting and using seamless tube products.

Annealing Process: Softening and Stress Relief

Annealing is a process where seamless tubes are heated to an appropriate temperature, held for a period, and then cooled slowly. Its main purposes are to reduce material hardness, improve machinability, and eliminate internal stresses. Depending on the heating temperature, annealing can be categorized into various types such as full annealing, process annealing, and stress relief annealing.

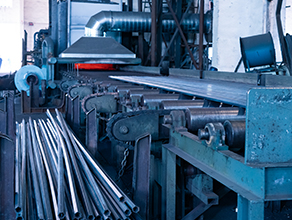

Tenjan Tube Co., Ltd. utilizes fully automated annealing furnaces to precisely control heating temperature and holding time, ensuring uniform microstructure and properties of the seamless tubes. Annealed seamless tubes exhibit lower hardness and good plasticity, making them particularly suitable for subsequent processing steps like cold bending and flaring.

Normalizing Process: Refinement and Homogenization

Normalizing is a heat treatment process where seamless tubes are heated to approximately 30-50°C above the Ac3 point, held, and then cooled in air. Compared to annealing, normalizing involves a faster cooling rate, resulting in a finer grain structure and improved strength and toughness of the material.

The normalizing process at Tenjan Tube Co., Ltd. is particularly suitable for carbon steel and low-alloy steel seamless tubes. Normalizing can eliminate banded structures, improve inhomogeneity in mechanical properties, and give the seamless tubes better overall performance. Tubes produced by this process are widely used in fields like machinery manufacturing and automotive components.

Quenching and Tempering: Strengthening and Toughening

Quenching and tempering is a combined heat treatment process where seamless tubes are first heated to the austenitizing temperature and rapidly cooled, followed by high-temperature tempering. Quenching gives the material high hardness and strength, while tempering improves toughness while maintaining strength, achieving an excellent strength-toughness combination.

The quenching and tempering production line at Tenjan Tube Co., Ltd. employs advanced temperature control systems to ensure precise and stable process parameters. Seamless tubes that undergo quenching and tempering possess excellent comprehensive mechanical properties and are particularly suitable for manufacturing critical components subjected to complex stresses, such as hydraulic cylinder barrels and transmission shafts.

Professional Advice on Process Selection

When selecting a heat treatment process for seamless tubes, it is necessary to comprehensively consider the service requirements, material characteristics, and cost factors. For applications requiring high plasticity and good machinability, the annealed condition is recommended. When a balance of strength and toughness is needed, normalizing is the optimal choice. For critical components with high requirements for strength and hardness, the quenching and tempering process should be selected.

Tenjan Tube Co., Ltd. has a professional technical team that can recommend the most suitable heat treatment solution based on customers' specific needs. The company is equipped with comprehensive heat treatment facilities and testing instruments to ensure that every batch of seamless tubes meets the expected performance requirements.

Conclusion

Heat treatment processes are key steps determining the performance of seamless tubes. Relying on advanced heat treatment equipment and extensive process experience, Tenjan Tube Co., Ltd. provides customers with high-quality seamless tube products in various heat-treated conditions. Whether it's annealing, normalizing, or quenching and tempering, the company can precisely control process parameters to ensure stable and reliable product quality. Please feel free to inquire for details about heat treatment processes; we will provide you with professional technical support and comprehensive after-sales service.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap