In industrial production, cold drawing and hot rolling are the two main production processes for seamless steel pipes, and they exhibit significant differences in performance and appearance. Understanding these distinctions helps users select the appropriate seamless steel pipe product based on their specific needs.

Intuitive Differences in Appearance Characteristics

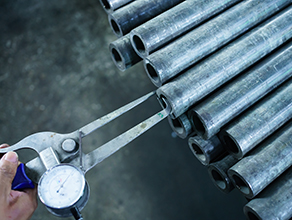

Visually, cold-drawn seamless steel pipes have a bright, silvery, and smooth surface with uniform texture and precise dimensions. This is because the cold-drawing process is carried out at room temperature, involving multiple passes of drawing and precision straightening, resulting in a surface roughness that can reach Ra ≤ 0.8μm. In contrast, hot-rolled seamless steel pipes have a dark gray surface with a slight oxide layer, and the surface is relatively rough, a natural phenomenon formed during the high-temperature rolling process due to contact with air.

Regarding dimensional accuracy, the outer diameter tolerance of cold-drawn seamless steel pipes can be controlled within ±0.05mm, with higher wall thickness uniformity. The dimensional tolerances for hot-rolled seamless steel pipes are relatively larger, typically with an outer diameter tolerance around ±0.5mm. Changzhou Tenjan Steel Pipe Co., Ltd. utilizes advanced production equipment to ensure that seamless pipes from both processes meet the required dimensional accuracy standards.

Significant Differences in Performance Characteristics

In terms of mechanical properties, cold-drawn seamless steel pipes undergo work hardening, resulting in higher strength and hardness. Their tensile strength is typically 10%-15% higher than that of hot-rolled pipes, but their plasticity is relatively lower. Hot-rolled seamless steel pipes retain better plasticity and toughness, making them more suitable for subsequent processing steps like bending and flaring.

Production data from Changzhou Tenjan Steel Pipe Co., Ltd. shows that the yield strength of cold-drawn seamless steel pipes can reach over 500 MPa, while the yield strength of hot-rolled pipes is typically around 345 MPa. This performance difference makes the two types of seamless steel pipes suitable for different working conditions and applications.

Selection Guide for Application Areas

Based on their different performance characteristics, cold-drawn seamless steel pipes are more suitable for precision hydraulic systems, automotive manufacturing, and instrumentation fields that require high dimensional accuracy and surface quality. Their excellent surface finish effectively reduces fluid flow resistance and improves system efficiency.

Hot-rolled seamless steel pipes are widely used in general industrial fields such as petroleum transportation, building structures, and machinery manufacturing. Their better plasticity and relatively lower cost offer significant advantages in large-volume, conventional applications. Changzhou Tenjan Steel Pipe Co., Ltd. can recommend the most suitable seamless steel pipe production process based on customers' specific requirements

Selection Advice

When selecting seamless steel pipes, it is advisable to comprehensively consider factors such as usage pressure, working environment, precision requirements, and cost budget. For high-pressure, high-precision applications, cold-drawn seamless steel pipes are the better choice; whereas for general pressure-bearing and structural purposes, hot-rolled seamless steel pipes offer better cost-effectiveness.

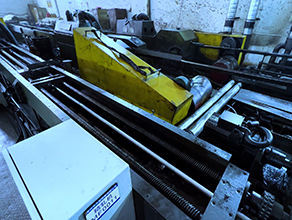

Changzhou Tenjan Steel Pipe Co., Ltd. possesses a comprehensive production system and quality control processes, enabling them to provide professional product selection advice. The company is equipped with advanced testing equipment to ensure that every seamless steel pipe meets quality standards, helping customers achieve optimal product selection.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap