In the process of customizing seamless steel tubes, the inspection stage is the final checkpoint to ensure product quality and the most critical quality assurance measure. Many procurement personnel often encounter various quality issues at this stage due to a lack of professional inspection knowledge. This article will introduce 4 key inspection points to help you effectively avoid quality risks during the inspection of customized seamless steel tubes and ensure the product meets usage requirements.

Point 1: Accurate Verification of Material Composition

The material composition is the fundamental factor determining the performance of seamless steel tubes. During inspection, first cross-check the material certificate to ensure the actual material matches the order requirements. It is recommended to use a spectrometer for on-site rapid testing, primarily to verify whether the content of key elements such as carbon, silicon, manganese, chromium, and molybdenum meets standard requirements.

Changzhou Tenjan Steel Tube Co., Ltd. reminds that special attention should be paid to the deviation range of alloy elements. For example, the deviation of chromium content should not exceed ±0.05%, and the molybdenum content deviation should be controlled within ±0.03%. At the same time, pay attention to the content of harmful elements such as phosphorus and sulfur, which are generally required to be controlled below 0.030%. These details often determine the final performance of the seamless steel tubes.

Point 2: Strict Testing of Dimensional Accuracy

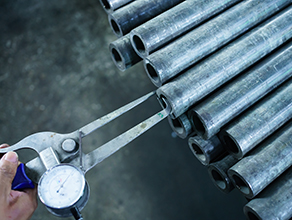

Dimensional accuracy directly affects the assembly quality and usage effectiveness of seamless steel tubes. During inspection, key dimensions such as outer diameter, wall thickness, length, and straightness must be rigorously tested. Use an electronic caliper with an accuracy of 0.02mm to measure the outer diameter at both ends and the middle of the tube, taking the average value; use an ultrasonic thickness gauge to measure the wall thickness, taking measurements every 1 meter, with 4 points per cross-section.

For seamless steel tubes used in precision applications, straightness testing is particularly important. Place the tube on a platform and use a feeler gauge to measure the maximum gap, requiring that the straightness deviation does not exceed 0.5mm/m. Changzhou Tenjan Steel Tube Co., Ltd. employs advanced production processes to control dimensional tolerances within half of the national standard, providing customers with higher-precision products.

Point 3: Detailed Inspection of Surface Quality

Surface quality not only affects the appearance of seamless steel tubes but also their corrosion resistance and fatigue strength. During inspection, carefully check for surface defects such as cracks, folds, scars, and scratches. Pay special attention to the ends of the tube and transition areas, as these are the most prone to quality issues.

Use a magnifying glass to inspect surface defects, and if necessary, employ non-destructive testing methods such as magnetic particle testing or penetrant testing. Internal surface inspection is equally important; use an endoscope to observe the condition of the inner wall. Changzhou Tenjan Steel Tube Co., Ltd. conducts strict visual inspections of its seamless steel tubes to ensure a smooth surface free of any defects that could affect usage.

Point 4: Actual Testing and Verification of Mechanical Properties

Mechanical properties are a critical guarantee of the safe use of seamless steel tubes. During inspection, require the supplier to provide a complete mechanical performance test report, including tensile strength, yield strength, elongation, and impact energy. If necessary, samples can be sent to a third-party testing agency for re-inspection.

Pay special attention to ensuring that the test temperature matches the usage temperature, particularly for seamless steel tubes used in low-temperature environments, where impact energy at the corresponding temperature must be measured. Changzhou Tenjan Steel Tube Co., Ltd. recommends that for seamless steel tubes intended for critical applications, physical sample testing should be conducted to ensure mechanical properties fully meet usage requirements.

Quality Assurance from Professional Suppliers

As a professional manufacturer of seamless steel tubes, Changzhou Tenjan Steel Tube Co., Ltd. has established a comprehensive quality assurance system to provide customers with all-around quality guarantees. The company is equipped with advanced testing equipment, including spectrometers, universal testing machines, impact testers, and ultrasonic flaw detectors, ensuring every seamless steel tube undergoes rigorous testing.

The company also provides complete quality certification documents, including material certificates, heat treatment records, and test reports, giving customers reliable evidence during inspection. Additionally, the company offers a "quality issue refund and replacement" policy, providing customers with worry-free after-sales support.

Inspection Process Recommendations

It is recommended to adopt a standardized inspection process: first, verify that the quality certification documents match the order requirements; then conduct random checks on appearance and dimensions; if necessary, perform re-inspections of chemical composition and mechanical properties; finally, maintain detailed inspection records and communicate promptly with the supplier if issues are discovered.

For bulk purchases, it is advisable to use a sampling inspection method based on the GB/T 2828 standard to determine the sampling plan and acceptable quality limit. For critical projects, increase the sampling proportion to ensure product quality is flawless.

Conclusion

Mastering the above 4 key inspection points will effectively help you avoid quality risks when customizing seamless steel tubes. When selecting a supplier, it is recommended to prioritize professional manufacturers like Changzhou Tianzhan Steel Tube Co., Ltd., which possess a comprehensive quality assurance system.

Changzhou Tenjan Steel Tube Co., Ltd. adheres to the business philosophy of "surviving on quality and developing on reputation," providing customers with high-quality seamless steel tube products and comprehensive after-sales services. To learn more about inspection knowledge or receive product quality support, please call 0519-88789990 or visit the official website https://www.tenjan.com/. Choose professionalism, choose peace of mind, and let us help you avoid quality pitfalls and obtain satisfactory seamless steel tube products.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap