In the procurement and use of seamless steel tubes, the delivery condition is a critical technical parameter that directly influences the material's microstructure, properties, and subsequent processability. Different heat treatment states, such as normalizing, annealing, and tempering, endow seamless steel tubes with entirely distinct performance characteristics. Understanding the differences between these heat treatment processes and their effects on performance is of great significance for the correct selection and use of seamless steel tubes.

Normalizing Treatment: Refining Grains and Improving Overall Performance

Normalizing is a heat treatment process in which seamless steel tubes are heated to 30-50°C above Ac3 or Accm, held at that temperature for an appropriate time, and then cooled in air. The main purposes of this process are to refine the grain size, homogenize the microstructure, eliminate internal stresses, and enhance the overall mechanical properties of the steel tubes.

Seamless steel tubes that have undergone normalizing treatment exhibit a balanced combination of moderate strength and good toughness, with slightly higher hardness than in the annealed state, as well as good machinability. Such tubes are typically used for manufacturing structural components and mechanical parts that require good overall mechanical properties. Normalizing treatment also eliminates overheating defects and prepares the microstructure for subsequent heat treatments.

Annealing Treatment: Reducing Hardness and Improving Processability

Annealing is a heat treatment process in which seamless steel tubes are heated to a suitable temperature, held for a certain period, and then slowly cooled. Depending on the objective, annealing can be classified into various types, such as full annealing, incomplete annealing, and isothermal annealing.

The primary goals of annealing are to reduce the hardness of seamless steel tubes, improve machinability, eliminate internal stresses, stabilize dimensions, and homogenize the microstructure and composition to enhance mechanical properties. Annealed seamless steel tubes have low hardness and good plasticity, making them easy to cold form. This state is particularly suitable for applications requiring extensive cold processing, such as bending and flaring.

Tempering Treatment: Stabilizing the Microstructure and Eliminating Stresses

Tempering is a heat treatment process in which seamless steel tubes that have been quenched or normalized are reheated to a temperature below Ac1, held for a certain time, and then cooled. The main purposes of tempering are to eliminate internal stresses generated during quenching or normalizing, stabilize the microstructure, adjust mechanical properties, and achieve the desired balance of strength and toughness.

Based on the tempering temperature, it can be categorized into low-temperature tempering, medium-temperature tempering, and high-temperature tempering. Low-temperature tempering (150-250°C) primarily aims to eliminate internal stresses while maintaining high hardness and wear resistance. Medium-temperature tempering (350-500°C) provides high elastic limits and yield strength. High-temperature tempering (500-650°C), also known as quenching and tempering, delivers excellent overall mechanical properties.

Impact of Heat Treatment State on Performance

Different heat treatment states significantly affect the performance of seamless steel tubes. Normalized tubes exhibit good overall mechanical properties with a balanced combination of strength and toughness. Annealed tubes have low hardness and good plasticity, making them easy to cold process. Tempering, on the other hand, allows for precise adjustment of the tube's properties to meet specific requirements.

Selecting the appropriate heat treatment state ensures the best cost-performance ratio for seamless steel tubes. For example, normalized tubes are suitable for structural components requiring higher strength, while annealed tubes are ideal for parts that need cold processing. For critical components requiring precise performance matching, a quenching and tempering treatment is necessary.

Recommended Professional Manufacturer

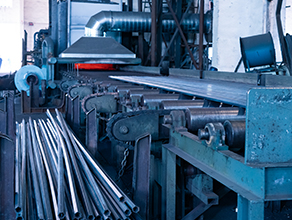

Changzhou Tenjan Steel Tube Co., Ltd. possesses comprehensive heat treatment equipment and a strict quality control system, enabling the company to provide seamless steel tube products in various states according to customer needs. The company is equipped with fully automated heat treatment production lines and utilizes advanced temperature control systems to ensure the stability and consistency of the heat treatment processes.

By employing scientific heat treatment parameters and precisely controlling heating temperature, holding time, and cooling rate, the company ensures that every batch of seamless steel tubes meets the expected performance requirements. Additionally, the company has complete testing facilities to conduct comprehensive inspections of hardness, metallographic microstructure, mechanical properties, and other parameters of the heat-treated tubes, ensuring stable and reliable product quality.

The technical team at Changzhou Tenjan Steel Tube Co., Ltd. can recommend the most suitable heat treatment state based on customer usage requirements and processing techniques, providing professional technical support and services.

Conclusion

Selecting the correct delivery condition for seamless steel tubes is crucial to ensuring product quality and performance. Different heat treatment states, such as normalizing, annealing, and tempering, impart distinct performance characteristics to seamless steel tubes, making them suitable for various application scenarios. It is recommended that users choose the most appropriate heat treatment state based on specific usage requirements and processing techniques.

With advanced heat treatment equipment and a professional technical team, Changzhou Tenjan Steel Tube Co., Ltd. can provide high-quality seamless steel tube products in various states. For more information on selecting heat treatment states or to request product samples, please call 0519-88789990 or visit the official website www.tenjan.com. Choose professionalism, choose suitability, and let us provide the highest-quality seamless steel tube solutions for your projects.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap