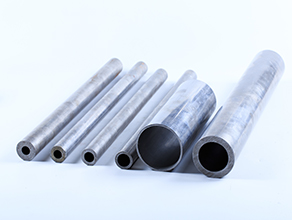

Seamless steel tubes, as crucial foundational materials in the industrial sector, have their quality directly impacting equipment performance and usage safety. When selecting and using seamless steel tubes, understanding the key factors influencing their quality is essential. This article provides an in-depth analysis of the core elements determining the quality of seamless steel tubes from multiple dimensions, offering professional reference for your procurement decisions.

Fundamental Impact of Raw Material Quality

The quality of the raw materials is the primary factor determining the quality of seamless steel tubes. High-quality steel billets require uniform chemical composition, low levels of harmful elements, and non-metallic inclusions controlled within reasonable limits. The purity of the steel billet directly affects the mechanical properties and durability of the seamless steel tube, especially the content of elements such as sulfur and phosphorus, which must be strictly controlled within standard limits.

The internal quality of the steel billet is equally important. Defects formed during the continuous casting process, such as center porosity and shrinkage cavities, can be extended and amplified during subsequent rolling processes, leading to internal cracks or delamination in the seamless steel tube. Therefore, strict raw material inspection and screening are fundamental steps in ensuring the quality of seamless steel tubes.

Critical Role of Production Process

The production process for seamless steel tubes includes various methods such as hot rolling and cold drawing, each with specific quality control points. During the hot rolling process, parameters such as the uniformity of heating temperature, control of rolling force, and distribution of deformation directly affect the final product quality. Excessively high temperatures may cause burning, while too low temperatures can easily generate cracks.

The cold drawing process imposes higher requirements on the dimensional accuracy and surface quality of seamless steel tubes. Factors such as mold design, drawing speed, and lubrication conditions require precise control. Reasonable process parameters not only ensure product dimensional accuracy but also improve the material's microstructure and properties, enhancing the overall quality level of the seamless steel tube.

Importance of Heat Treatment Process

Heat treatment is a key process for enhancing the performance of seamless steel tubes. Through different heat treatment processes such as normalizing, annealing, and quenching, the material's microstructure can be adjusted, mechanical properties improved, and internal stresses eliminated. Proper heat treatment enables the seamless steel tube to achieve an ideal combination of strength, hardness, and toughness.

Temperature control, holding time, and cooling rate during the heat treatment process require precise management. Uneven temperatures can lead to variations in microstructure and properties, insufficient holding time prevents complete microstructural transformation, and improper cooling rates may generate new internal stresses. These factors directly impact the performance of the seamless steel tube in service.

Dimensional Accuracy and Surface Quality

The dimensional accuracy of seamless steel tubes includes multiple indicators such as outer diameter, wall thickness, ovality, and straightness. Precise dimensional control not only affects assembly quality but also relates to the uniformity of load-bearing capacity. Tubes with uneven wall thickness will fail first at the thinnest points when under internal pressure, seriously compromising service safety.

Surface quality is a crucial indicator for assessing the quality of seamless steel tubes. Defects such as surface cracks, folds, and scars can become stress concentration points, potentially initiating failure during use. High-quality seamless steel tubes should have a smooth, uniform surface free of significant processing defects.

Inspection and Quality Control System

A comprehensive inspection system is a vital safeguard for ensuring the quality of seamless steel tubes. Strict quality control points must be established at each stage, from raw material intake to finished product dispatch. Essential inspection items include chemical composition analysis, mechanical property testing, and non-destructive testing.

Modern seamless steel tube manufacturers commonly employ automated inspection equipment, such as ultrasonic testing, eddy current testing, and magnetic particle inspection, which can effectively detect internal and surface defects in the products. A sound traceability system ensures that the quality of each batch of products is controllable and traceable.

Technological Innovation and Continuous Improvement

In a competitive market, technological innovation has become a key driver for improving the quality of seamless steel tubes. The application of new processes and equipment continuously pushes the enhancement of product quality. For example, the application of controlled rolling and controlled cooling technologies has significantly improved the microstructure and properties of seamless steel tubes.

The philosophy of continuous improvement in quality management also profoundly influences the product quality of seamless steel tubes. By constantly optimizing production processes and perfecting quality management systems, seamless steel tube manufacturers can continuously elevate their product quality levels to meet market demand for high-quality products.

Conclusion

The quality of seamless steel tubes is influenced by multiple factors including raw materials, production processes, heat treatment, dimensional control, and quality inspection. Selecting a high-quality seamless steel tube supplier requires comprehensive consideration of their technical capabilities, equipment level, quality management system, and other competencies.

Changzhou Tenjan Steel Tube Co., Ltd., as a professional manufacturer of seamless steel tubes, always prioritizes product quality. The company possesses advanced production equipment and comprehensive testing methods, having established a strict quality management system to ensure that products leaving the factory comply with relevant standard requirements. The company's technical team is experienced and capable of providing professional product solutions and comprehensive after-sales service based on customer needs.

For more technical information on seamless steel tubes or product selection advice, please feel free to contact Changzhou Tenjan Steel Tube Co., Ltd. We are committed to providing the most suitable seamless steel tube products with professional expertise and high-quality service.

Tel: 0519-88789990

Website: https://www.tenjan.com/

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap