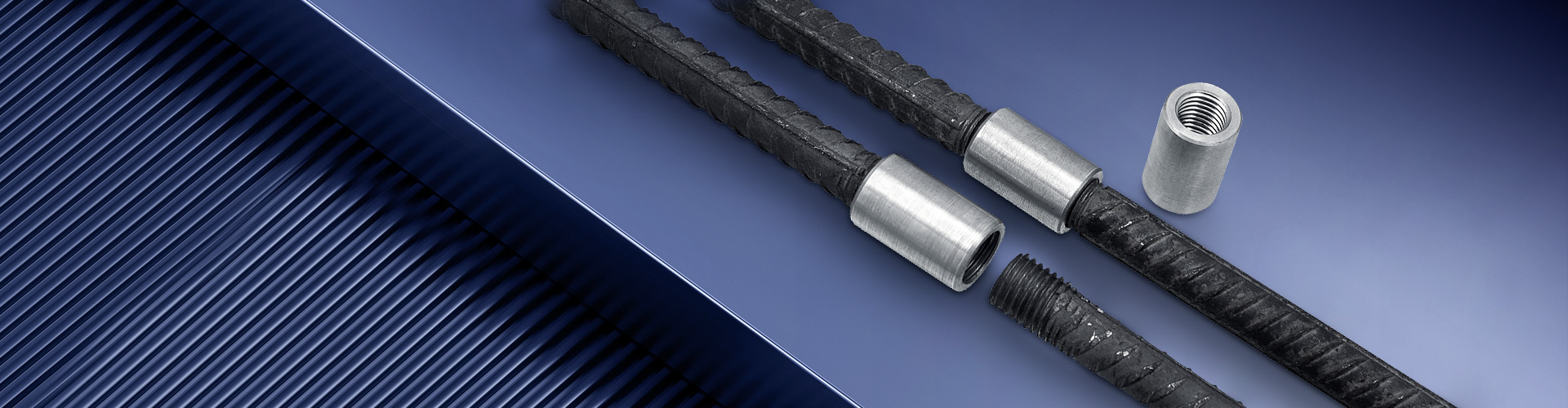

The Rolling Straight Thread Rebar Coupler System stands as the industry benchmark for high strength coupler applications. This rebar splices and coupler system is engineered to deliver unmatched performance in structural reinforcement splicing. As a leading manufacturer, Tenjan provides this position rebar coupler solution designed for simple, precise, and robust installations. It ensures flawless reinforcement continuity for projects ranging from high-rise cores to critical infrastructure, performing reliably under diverse environmental stresses. Our High Strength Coupler products [Rolling Straight Thread Coupler: For Precision Rebar Splices] comply with global standards like JGJ 107 and ISO 15835, offering a perfect blend of ultimate tensile performance and unrivaled construction efficiency.

Structural Design & Precision Engineering

The excellence of our rebar splices and coupler system lies in its simplicity and precision. The core component is a high-strength forged steel coupler with internal parallel threads rolled to exacting tolerances. This position rebar coupler is designed to create a perfect full-thread engagement with the pre-threaded ends of rebars. This pure mechanical splice ensures direct axial load transfer, relying on the integrity of the threaded connection without any fillers or adhesives. The design of this high strength coupler maximizes the inherent material capacity of the rebar, making it the most reliable and efficient splicing method available.

Performance Advantages & Core Benefits

Choosing our Rolling Straight Thread Coupler translates into significant project advantages. Its foremost benefit is providing a truly high strength coupler connection that consistently achieves 100% of the rebar's tensile strength. This makes it an ideal rebar splices and coupler solution for seismic and dynamic load applications. As a precise position rebar coupler, it allows for accurate reinforcement alignment and offers exceptional long-term stability with zero risk of vibration loosening. The system guarantees consistent, verifiable quality in every splice, enables dramatic installation speed, and provides superior durability in corrosive environments, delivering outstanding value and performance.

Applications & Industry Solutions

This versatile rebar splices and coupler system is fundamental across the construction spectrum. It is the preferred high strength coupler for vertical column splices in skyscrapers and shear wall connections. In infrastructure, it serves as a critical position rebar coupler in bridge piers, tunnel linings, and dam structures. The industrial and energy sectors rely on it for nuclear plant containment and heavy industrial foundations, where reliable rebar splices are non-negotiable. Its adaptability for precast concrete connections and general commercial use underscores its status as a universal, high-performance splicing solution.

Tenjan's Commitment: Quality & Service

Tenjan elevates the standard rebar splices and coupler into a guaranteed system. As a source factory, we control every step, ensuring each high strength coupler meets rigorous specifications. Our expertise provides complete technical support, from selection to installation guidance for this precision position rebar coupler. We offer full certification packages and custom solutions, ensuring reliable supply, competitive pricing, and professional partnership for all your critical rebar connection needs.

Reliability & Environmental Suitability

Engineered for permanence, our high strength coupler system exhibits exceptional environmental resilience. It performs consistently in temperature extremes, high humidity, and chemically aggressive settings. The all-metal, mechanical connection of this rebar splices and coupler is inherently corrosion-resistant and maintenance-free. This makes our position rebar coupler ideal for marine environments, transportation infrastructure, and structures in active seismic zones, ensuring lifelong structural integrity and total project confidence.

By integrating precision engineering with robust manufacturing, Tenjan's Rolling Straight Thread Rebar Coupler System delivers more than a splice—it delivers certainty. It is the definitive choice for high strength, reliable rebar splices and coupler applications worldwide.

| Parameter | Key Features |

| Product Name | Rolling Straight Thread Rebar Coupler,Upsetting Parallel Thread Rebar Coupler,Cold Extrusion Press Rebar Coupler,Taper Thread Rebar Coupler,Customized Special Shape Rebar Coupler,Bolted Rebar Coupler |

| Material | Carbon Steel ASTM 1045 (45#) / Alloy Steel ASTM 5140 (40Cr) |

| Standard | Comply with Chinese standard JG/T 163-2013 Couplers for Rebar Mechanical Splicing, Amercian standard ACI318 ACI349, British standards BS8110, French standard NF35-20-1, German standard DIN1045, ISO 15835 and other relevant standards. |

| Used for rebar Grade | BS 4449, B500, JG/T 163-2013, HRB 400, HRB 500, HRB600, ASTM A615 Grade 60/Grade 75 |

| Size | Suitable for rebar size from 16mm to 32mm |

| Thread | 60⁰/ 75⁰ |

| Packing | Wooden Case + Carbon Box |

| Customization | Customizing based on required major diameter, pitch of thread, minimum tensile strength and rebar strength |

| Size of Rebar | Outer Diameter(mm) | Length(mm) | Thread(M*P) | ||||

| Ф16 | 24 | 40 | M16.55*2.5 | ||||

| Ф18 | 27 | 45 | M18.65*2.5 | ||||

| Ф20 | 30 | 50 | M20.65*2.5 | ||||

| Ф22 | 32.5 | 55 | M22.65*2.5 | ||||

| Ф25 | 37 | 60 | M25.65*3.0 | ||||

| Ф28 | 41.5 | 65 | M28.65*3.0 | ||||

| Ф32 | 47.5 | 72 | M32.65*3.0 | ||||

| Ф36 | 53 | 80 | M36.65*3.0 | ||||

| Ф40 | 59 | 88 | M40.65*3.0 | ||||

| Ф50 | 74 | 108 | M50.65*3.5 |

Upsetting Parallel Thread Rebar Coupler

Rolling Straight Thread Rebar Coupler

Cold Extrusion Press Rebar Coupler

Bolted Rebar Coupler

Taper Thread Rebar Coupler

Customized Special Shape Rebar Coupler

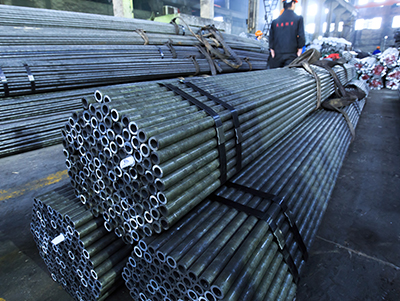

1.Raw Material CustomizationOwing the entire seamless steel tube production line, Tenjan can customize rebar couplers starting from tube production according to requirement.

2.Coupler Breaking Force CustomizationBased on being an expert in material properties, Tenjan can design the rebar coupler breaking force based on the rebar standard and grade to save the overall cost for customer.

3.Standards ComplianceIn compliance with ACl318, JGJ107, UBC 1997,BS8110, NF35-20-1,DIN1045,ISO 15835.

4.Size CustomizationDesign and customize according to customers' required major diameter, pitch of thread, Length.

Tenjan Rebar Couplers are widely used in nuclear power plants, sea-crossing bridges, water conservancy dams, buildings, etc. Exported to over 20 countries across six continents, and have been consistently trusted by global customers.

Hangzhou Bay Bridge

Indonesia Jatigede Dam

Pakistan Kohala Hydropower Station

Penang Second Bridge, Malaysia

Russian Federation Tower

Zemun-Borca Bridge, Serbia

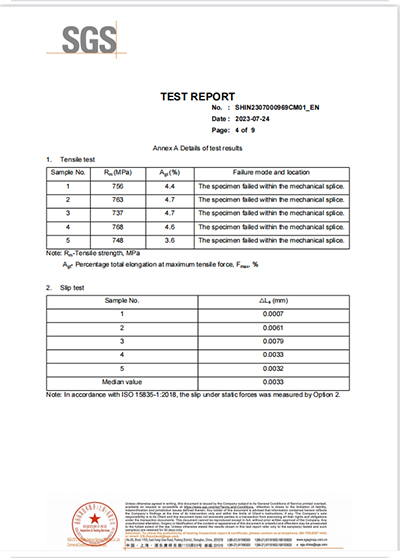

TUV Test for the seamless steel tube(the raw material of rebar coupler)

SGS Testing Report(Tensile Test-Slip Test)

Certificate-of-Approval

ISO-certificate-of-Conformity

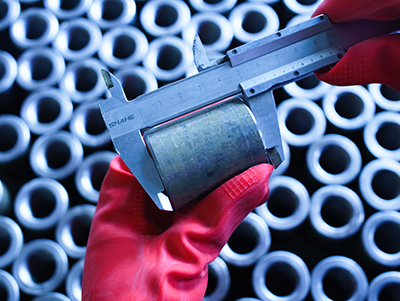

Every batch of rebar coupler can be traced and guaranteed, following lSO9001.

Roud Bar

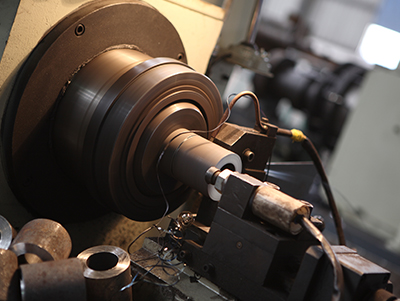

Tube Production

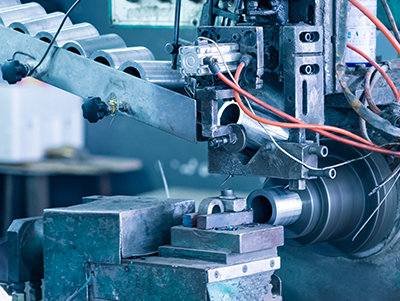

Cutting

Chamfer

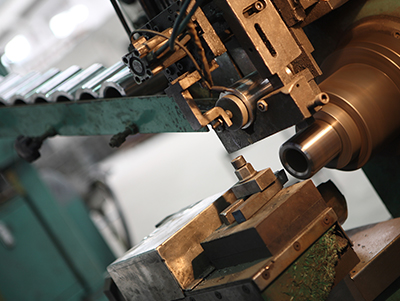

Machining OD

Threading

Laser Marking

Anti-Rust

Package

Shipping

We Have A Professional Team To Provide Design+ R&D+ Customization + Customer VlP Service

1

Raw Materia Identification &Traceability

2

Seamless Steel Tube Inspection

3

Seamless Steel Tube Tensile Strength Testing

4

In-process Size Checking

5

Coupler Breaking Force Testing

6

Coupler Threading Checking(WITH GO & NO-GO GAUGE)

7

Finished Coupler Size Checking

8

Finished Coupler Surface Checking

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap