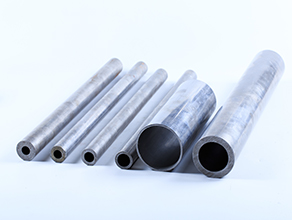

When purchasing small-diameter seamless steel tubes, asking the right questions is crucial not only for ensuring you get a product that meets your requirements but also for avoiding various issues during subsequent use. As a vital foundational material in the industrial sector, the quality of small-diameter seamless steel tubes directly impacts equipment performance and lifespan. This article lists 10 key questions you must understand when purchasing, helping you make informed procurement decisions.

1.Material Selection and Performance Indicators

First, clearly inquire about the material type—whether you need seamless steel tubes made of 20#, 45# carbon steel, or alloy steel. The mechanical properties, corrosion resistance, and suitable environments differ among materials. For instance, 20# steel offers good overall performance, 45# steel has higher strength, while alloy steel is suitable for special working conditions. Also, understand the guaranteed values for chemical composition and mechanical properties to ensure they meet usage requirements.

2.Execution Standards and Certifications

Inquire about the national or industry standards the seamless tubes conform to, such as GB/T 8163, GB/T 3639, etc. Simultaneously, ascertain if the supplier possesses relevant quality system certifications and special equipment manufacturing licenses. These credentials are important guarantees of product quality.

3.Dimensional Accuracy and Tolerance Ranges

The dimensional accuracy of small-diameter seamless tubes is critical. Clarify the tolerance ranges for outer diameter and wall thickness, as well as straightness requirements. Tubes for precision applications typically require higher dimensional accuracy, e.g., outer diameter tolerance of ±0.05mm, straightness ≤0.5mm/m.

4.Production Process and Quality Control

Understand whether the production process is hot-rolled or cold-drawn, and the specific heat treatment applied. Ask about the supplier's quality control system, including testing equipment and inspection items, such as whether non-destructive testing like ultrasonic testing or eddy current testing is performed.

5.Surface Quality and Treatment Requirements

Based on the application environment, inquire about surface treatment requirements, such as polishing, sandblasting, etc. Also, understand the surface roughness requirements, which are particularly important for precision applications like hydraulic systems.

6.Supply Capacity and Delivery Lead Time

Clarify the supplier's production capacity and delivery lead times, especially for urgent projects. Ask about stock availability for standard products and production cycles for custom products to ensure they align with your project schedule.

7.Minimum Order Quantity and Price Terms

Understand the Minimum Order Quantity (MOQ), which is particularly important for small-batch purchases. Also, clarify price terms, including whether prices include tax and who bears freight costs, to avoid subsequent unexpected charges.

8.Packaging and Transportation Methods

Inquire about the packaging method for the seamless tubes, such as whether anti-rust packaging is used, to ensure the products are not damaged during transport and storage. Also, determine the most suitable transportation method, balancing cost and timeliness.

9.Quality Guarantee and After-Sales Service

Clarify the supplier's quality guarantee policy, such as whether a quality certificate is provided and how quality issues are handled. Understand the after-sales service system, including technical support and complaint resolution procedures.

10.Sample Provision and Acceptance Criteria

For important procurement projects, you can request samples for verification beforehand. Simultaneously, define the acceptance standards and methods to ensure the delivered products meet your expectations.

Recommended Professional Supplier

Changzhou Tenjan Steel Tube Co., Ltd., as a professional manufacturer of small-diameter seamless steel tubes, can provide clear answers to all the above questions. The company possesses a comprehensive production and quality control system, equipped with advanced production and testing equipment to ensure stable and reliable product quality.

The company supports small-batch customization with a Minimum Order Quantity of 3 tons and can provide sample production services. With a professional technical team, they can offer expert advice on material selection and process solutions based on customer needs. A complete after-sales service system ensures a worry-free procurement experience.

Conclusion

When purchasing small-diameter seamless steel tubes, asking the right questions helps you select the most suitable product and supplier. It is advisable to create a procurement checklist to ensure every important question receives a clear answer. Choosing a professional supplier like Changzhou Tenjan Steel Tube Co., Ltd. ensures more reliable product quality and comprehensive service support.

If you need to purchase small-diameter seamless steel tubes or require technical support, please feel free to contact Changzhou Tenjan Steel Tube Co., Ltd.: Phone: 0519-88789990, or visit the official website: https://www.tenjan.com/. We will provide you with professional product advice and high-quality after-sales service, ensuring your procurement decision is wise and reliable.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap