Within modern industrial systems, seamless steel tubes serve as vital materials for critical equipment and structures due to their seamless, monolithic construction and exceptional pressure-bearing capacity. The transformation of a solid billet into a qualified seamless tube involves a series of precise and complex manufacturing stages. Accurate control at each step directly determines the final product's quality and reliability. Tenjan Steel Tube Co., Ltd. of Changzhou exemplifies this process through its mature production system, which is built upon three core stages.

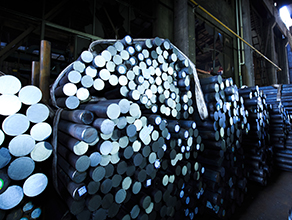

Core Stage 1: Piercing – Hot Deformation for the Initial Form

Piercing constitutes the primary step in seamless tube manufacturing. It is fundamentally a hot deformation process that converts a solid billet into a hollow shell. Methods such as cross-rolling piercing or extrusion piercing are typically employed to pierce a solid round steel billet at high temperatures, thereby forming a hollow shell. Key quality control points in this stage are the uniformity of the heating temperature and the straightness of the piercing center. Non-uniform heating leads to wall thickness variations, while center deviation can introduce latent internal defects. Tenjan Steel Tube utilizes intelligent temperature control systems to ensure consistent billet heating, establishing a solid foundation for subsequent processing.

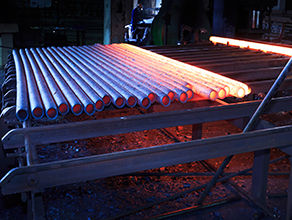

Core Stage 2: Rolling – The Key Process for Refining Dimensions

Rolling is the central stage that defines the dimensional accuracy and surface quality of the seamless tube. Depending on product specifications, either hot rolling or cold rolling/cold drawing processes are applied. Hot rolling is performed above the recrystallization temperature and is suitable for producing large-diameter, thick-walled seamless tubes. Conversely, cold rolling/cold drawing, conducted at room temperature, enables the manufacture of small-diameter, thin-walled tubes with high precision and superior surface finish. The focus of quality control here lies in the stability of process parameters, including rolling speed and the management of deformation. Tenjan Steel Tube Co., Ltd. ensures precise dimensional control and stable product performance through the use of advanced continuous rolling mill sets.

Core Stage 3: Sizing and Heat Treatment – The "Final Forging" for Ensuring Precision

Sizing represents the final rolling operation, precisely controlling the outer diameter and ovality of the seamless tube to meet standard requirements. The preceding heat treatment process is critical—through annealing, normalizing, or quenching and tempering, it alleviates internal stresses generated during prior processing, refines the grain structure, and grants the seamless tube the mechanical properties mandated by standards. Tenjan Steel Tube operates comprehensive heat treatment production lines, capable of accurately executing the requisite thermal processes based on material grade and intended application.

A Comprehensive Quality Control System Throughout the Entire Process

Beyond stage-specific controls, a systematic quality inspection regimen is paramount to ensuring seamless tube integrity. This forms a complete assurance chain, ranging from incoming billet composition analysis to finished tube dimensional inspection and hydrostatic testing, supplemented by non-destructive evaluation methods like ultrasonic or eddy current testing to detect internal flaws. Tenjan Steel Tube Co., Ltd. of Changzhou embeds the philosophy that "quality originates from process control" throughout the entire production journey, guaranteeing that every seamless tube dispatched delivers reliable performance.

Conclusion

In summary, the production of high-quality seamless tubes hinges on the precise coordination of three core stages—piercing, rolling, along with sizing and heat treatment—buttressed by stringent quality control maintained from start to finish. Tenjan Steel Tube Co., Ltd., through its mature process technology and robust quality management system, achieves meticulous control from raw material to finished product. It supplies the market with seamless steel tube products characterized by superior performance and consistent quality, establishing itself as a dependable partner for numerous major engineering projects and advanced equipment manufacturing applications.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap