Cracking in seamless steel tubes during use is a serious quality incident, which not only affects the normal operation of equipment but may also pose safety hazards. In-depth analysis of the causes of seamless steel tube cracking and the adoption of effective preventive measures are of great significance for ensuring equipment safety. This article systematically analyzes the main causes of seamless steel tube cracking and provides professional solutions.

Cracking Induced by Material Quality Defects

Inherent quality issues in the material itself are the primary factor leading to seamless steel tube cracking. Defects such as excessive non-metallic inclusions, chemical composition segregation, and internal pores can create stress concentration points within the tube. Under load, these points can gradually propagate into cracks. Especially when the content of harmful elements like sulfur and phosphorus is too high, the toughness and plasticity of the material are significantly reduced, increasing the risk of cracking.

Seamless Steel Pipe Finished Products Warehouse

Changzhou Tenjan Tube Co., Ltd. addresses this issue through stringent raw material control. The company uses a spectrum analyzer to test the composition of each batch of raw materials, ensuring the chemical composition meets standard requirements.

Defects Caused by Improper Manufacturing Processes

The manufacturing process of seamless steel tubes directly affects their internal microstructure and properties. Excessive piercing temperature may lead to burning, while too low a temperature can easily cause cracks. Improper rolling process parameters can cause microstructural inhomogeneity. Inadequate control of cooling rates can generate residual stresses. These issues during manufacturing can all lay the groundwork for cracking during subsequent use.

To address this problem, Changzhou Tenjan Tube Co., Ltd. has established a comprehensive process control system. An automated temperature control system ensures precise and controllable heating temperatures; rolling process parameters are optimized to guarantee uniformity of the microstructure; and controlled cooling is implemented to effectively eliminate residual stresses. These measures significantly improve the manufacturing quality of seamless steel tubes.

Impact of Non-Standard Heat Treatment Processes

Heat treatment is a key process determining the properties of seamless steel tubes. Insufficient annealing can lead to excessive hardness and insufficient toughness. Improper quenching temperatures can cause abnormal microstructures. Inadequate tempering fails to effectively relieve internal stresses. These heat treatment defects all reduce the material's resistance to cracking.

Changzhou Tenjan Tube Co., Ltd. is equipped with fully automated heat treatment production lines, using computers to precisely control process parameters. Protective atmosphere heat treatment technology is employed to prevent surface oxidation and decarburization. Strict heat treatment process specifications are established to ensure stable performance for each batch of products. Full-process monitoring is implemented to guarantee traceability of heat treatment quality.

Usage Conditions Exceeding Design Limits

If seamless steel tubes are used under conditions exceeding their design specifications, cracking is also prone to occur. Operating pressure surpassing allowable values, excessive temperature fluctuations, or excessively corrosive media can all accelerate material damage. Particularly, fatigue failure under alternating loads is a common form of cracking in seamless steel tubes.

Damage Induced by Environmental Factors

Corrosive environments are a significant factor leading to seamless steel tube cracking. Environmentally sensitive fractures like stress corrosion cracking and hydrogen-induced cracking are often sudden and highly hazardous. Especially in high-temperature and high-pressure environments, the action of corrosive media significantly accelerates the cracking process.

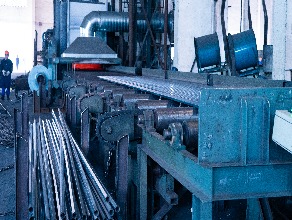

Seamless Steel Pipe Heat Treatment Process

Quality Control and Preventive Measures

Changzhou Tenjan Tube Co., Ltd. has established a comprehensive quality control system to prevent cracking issues. From raw material warehousing to finished product shipment, multiple inspection procedures are implemented: ultrasonic flaw detection for internal defects, eddy current testing for surface quality, and mechanical property tests to verify material performance. These measures ensure the reliability of outgoing products.

The company also provides complete technical services to help users with correct selection and use. Regular follow-ups with users allow understanding of product performance in service, enabling timely identification and resolution of potential problems. This full-process quality control model effectively prevents the occurrence of seamless steel tube cracking incidents.

Conclusion

Seamless steel tube cracking results from the combined effect of multiple factors, requiring prevention across various stages including material, manufacturing, and usage. Choosing a reliable supplier and ensuring correct selection and use are key to avoiding cracking problems.

Relying on stringent quality control and professional technical services, Changzhou Tenjan Tube Co., Ltd. provides users with high-quality seamless steel tube products. The company is committed to full-process tracking of product quality to ensure user safety. For more product information or technical support, please call 0519-88789990 or visit the official website at https://www.tenjan.com/.

Home Product Capabilities Case Studies Blogs About Get a Quote

Pipe & Tube Manufacturing Process Shapes & Profiles Pipes & Tubes Material Standard Steel Pipes & Tube Rebar Couplers Cold Drawn Steel Profiles & Bars

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap