In the automotive manufacturing industry’s journey toward a new era of "lightweighting," reducing weight has become a core trend in the sector’s development. Seamless steel tubes, with their excellent strength-to-weight ratio and design flexibility, are emerging as critical materials in automotive lightweighting technology. This traditional industrial material is gaining renewed vitality in the era of new energy vehicles, offering lightweight solutions for automakers.

Material Innovation in Lightweighting Technology

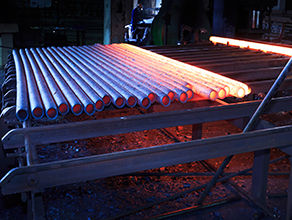

Automotive lightweighting is not only about reducing energy consumption but also about enhancing vehicle performance and safety. Seamless steel tubes demonstrate unique advantages in lightweight applications: through optimized cross-sectional design and wall thickness control, they significantly reduce weight while ensuring strength. Compared to solid components, parts manufactured using high-strength seamless steel tubes can achieve a weight reduction of 30% to 50%.

Innovative Applications in New Energy Vehicles

In the field of new energy vehicles, seamless steel tubes are even more widely used. Battery pack protection frames made of high-strength seamless steel tubes ensure crash safety while controlling overall weight. Motor casings processed from seamless steel tubes provide excellent heat dissipation and structural strength.

The chassis system is a key area for seamless steel tube applications. Components such as anti-collision beams and suspension arms, made from high-strength seamless steel tubes, improve vehicle handling and safety while reducing weight. Seamless steel tubes are also increasingly used in body-in-white structures, replacing traditional stamped and cast parts.

Technological Innovation Driving Lightweighting Development

Advancements in seamless steel tube production processes have opened up more possibilities for automotive lightweighting. Precision cold-rolling technology enables wall thickness tolerances to be controlled within ±0.1mm, ensuring part accuracy and consistency. Advanced heat treatment processes optimize the material’s mechanical properties, achieving the best balance between strength and weight.

Changzhou Tenjan Steel Tube Co., Ltd. has developed a series of specialized seamless steel tubes for automotive applications. Using unique alloy designs and heat treatment processes, these tubes achieve yield strengths of over 800MPa while maintaining good formability and weldability. These high-performance seamless steel tubes are widely used in new energy vehicle models from several well-known automotive brands.

Perfect Combination of Safety and Economy

In the process of automotive lightweighting, safety remains the top priority. High-strength seamless steel tubes, through rational structural design, ensure crash safety while reducing weight. Optimized seamless steel tube structural components perform excellently in crash tests, effectively absorbing and dispersing impact energy.

From a full lifecycle cost perspective, using seamless steel tubes for lightweighting also offers significant economic benefits. Weight reduction directly lowers energy consumption and extends driving range. Additionally, the durability and reliability of seamless steel tube components reduce maintenance costs.

Technical Support from Professional Manufacturers

As a specialized supplier of seamless steel tubes for automotive applications, Changzhou Tenjan Steel Tube Co., Ltd. is committed to providing innovative solutions for automotive lightweighting. The company has a comprehensive technology R&D system and is equipped with advanced production and testing facilities, enabling it to offer customized product development services based on customer needs.

The company’s automotive seamless steel tubes are certified under the IATF 16949 quality management system, with product performance fully meeting automotive industry requirements. Through continuous technological innovation and process optimization, the company helps customers achieve lightweighting goals while ensuring product quality.

Future Development Trends

As automotive lightweighting technology continues to evolve, the application of seamless steel tubes will become even more widespread. Future trends include developing higher-strength materials, optimizing cross-sectional designs, and innovating connection processes. Smart manufacturing technologies will also enhance the production efficiency and quality stability of seamless steel tubes.

Changzhou Tenjan Steel Tube Co., Ltd. will continue to increase R&D investment to develop more advanced seamless steel tube products, providing technical support for automotive lightweighting. The company has established partnerships with several automakers to jointly advance the development of lightweighting technology.

Conclusion

Against the backdrop of the "lightweighting" era, seamless steel tubes, as key materials for automotive lightweighting, are playing an irreplaceable role. Their excellent performance characteristics and continuously innovative application technologies provide crucial support for the sustainable development of the automotive manufacturing industry.

Changzhou Tenjan Steel Tube Co., Ltd. will, as always, provide customers with high-quality seamless steel tube products and technical services, supporting the automotive industry in achieving its lightweighting goals. For more information or technical support, please call 0519-88789990 or visit the official website at https://www.tenjan.com/. Let us work together to advance automotive lightweighting technology and create a new era of green mobility.

Home Tubes and Pipes Capabilities Case Studies Blogs About Get a Quote

Seamless Steel Tubes Special-Shaped Seamless Steel Tubes Cold Drawn Steel Profiles & Bars Cold-Drawn Welded Tubes Rebar Couplers

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap